Steel Roof Sheeting

Standing-seam panel and glazing system that adapts to any project - big or small

Galvanized

(Only Available from our JHB Branch)

Available in IBR, Corrugated and Widespan Profiles only and is manufactured according to your Specifications, you may order any length from 1.8m’s up to 13m’s.

- We offer the following thicknesses:

- Corrugated, IBR & Widespan in / 0.4mm / 0.5mm / 0.8mm

- Approximate lead time on Production is +- 8 days

- Deliveries are available – it is the customers responsibility to offload the truck so please ensure that you wear gloves

- *Standard Building regulations require 0.5mm AZ150 or stronger

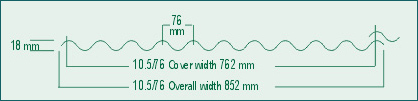

Corrugated

IBR

Wide Span

ZINCAL Roof Sheeting

(only available from our jhb branch)

Available in 0.5mm only.

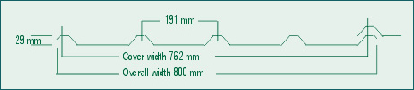

Innovative methods and production techniques are taking steel to new levels of strength, formability and versatility. In Aluzinc, the durability and service life of modern coated steel is extended even further.

Aluzinc is produced by a unique, efficient process whereby rolled steel is continuously hot dipped into a 55% Aluminium, 43.5% Zinc and 1.5% Silicon Alloy.

This patented coating protects the steel in two ways:

- The aluminium component of the coating provides a tough physical barrier between the extreme atmospheric conditions and the inner core of steel.

- The zinc in the coating provides sacrificial protection and also protects the steel at the cut edges.

- Thickness: 0.27mm 0.38mm 0.47mm 0.53mm 0.8mm

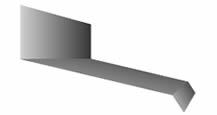

Flashings

Sheeting Direct supplies a full range of flashings to customers’ requirements. The standard range of flashings as summarized below is manufactured in 3 m lengths. Non-standard flashings are available on enquiry in different colours, lengths and dimensions.

Corner Flashing 460g

Internal Corner Flashing 460g

Gable Flashing 460g

IBR Ridging 460g

Roll Top 460g

Valley Flashing 460g

Sidewall Flashing 305g

Headwall Flashing 305g

Counter Flashing 150g

Broad Flute Closures

Narrow Flute Closures

Drip Flashing 150g

Drip Flashing 150g

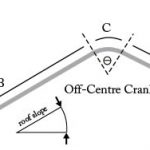

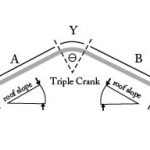

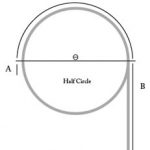

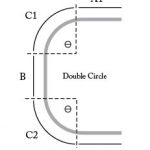

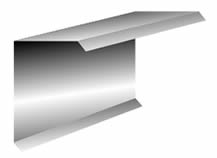

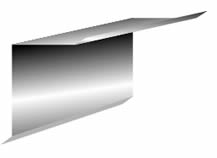

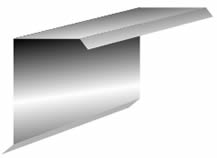

Bullnoses & Center Cranks

Bullnosing and centre-cranking of a profiled sheet incorporate lateral rib indentations pressed in at a uniform distance of 25 mm. Standard bullnoses are made with narrow flute uppermost and the bend away from the angular inclination. Reverse bullnoses are made with the bend into the narrow flute. Bullnoses and cranks can be at the end of a sheet or at any position along the length. Bullnoses and centre cranks can be manufactured in radii ranging from 350 mm to 800 mm for bullnoses which are bent through 0 – 135°. High tensile material can only be bullnosed and cranked to a minimum radius of 450 mm.